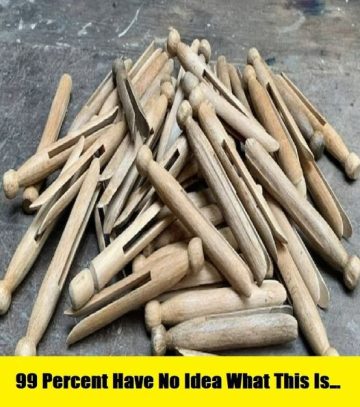

A Game-Changer for Laundry

The clothespin design familiar to us today was patented by David M. Smith of Vermont in 1853. According to his patent dated October 25 of that year, his clothespins “are hinged together” by a wire, “so that the two longer legs may be moved toward each other and at the same time move the shorter ones apart.”

This clamping mechanism allowed the pins to grip clothing securely without damage, while the spring ensured they stayed fastened even on windy days.

Smith wrote in the patent: “Another advantage and a very important one too, [what] my improved clothes pin possesses over the common pin is that it cannot be detached from the clothes by the wind as is the case with the common pin and which is a serious evil to washerwomen.”

Mass Production and Mainstream Popularity

With the advance of industrialization in the late 19th and early 20th centuries, the production of wooden clothespins became more automated. Factories began to manufacture standardized pins in large numbers, making them affordable and widely available.

Even throughout the 20th century, with the introduction of plastic alternatives, wooden clothespins remained a household staple thanks to their simplicity, durability, and low cost — especially for those without modern drying machines.

Today, they’re still produced and used around the world, often for crafts as well as laundry. They’re appreciated for their nostalgic charm and environmentally friendly materials.

Though plastic versions are more common in some areas due to their mass-market appeal, the wooden clothespin remains a symbol of traditional home life and sustainable living.

So what’s the greater laundry tragedy: socks vanishing in the wind or disappearing in the dryer? Let us know what you think of this story — and be sure to share it so others can weigh in too!

A Game-Changer for Laundry

The clothespin design familiar to us today was patented by David M. Smith of Vermont in 1853. According to his patent dated October 25 of that year, his clothespins “are hinged together” by a wire, “so that the two longer legs may be moved toward each other and at the same time move the shorter ones apart.”

This clamping mechanism allowed the pins to grip clothing securely without damage, while the spring ensured they stayed fastened even on windy days.

Smith wrote in the patent: “Another advantage and a very important one too, [what] my improved clothes pin possesses over the common pin is that it cannot be detached from the clothes by the wind as is the case with the common pin and which is a serious evil to washerwomen.”

Mass Production and Mainstream Popularity

With the advance of industrialization in the late 19th and early 20th centuries, the production of wooden clothespins became more automated. Factories began to manufacture standardized pins in large numbers, making them affordable and widely available.

Even throughout the 20th century, with the introduction of plastic alternatives, wooden clothespins remained a household staple thanks to their simplicity, durability, and low cost — especially for those without modern drying machines.

Today, they’re still produced and used around the world, often for crafts as well as laundry. They’re appreciated for their nostalgic charm and environmentally friendly materials.

Though plastic versions are more common in some areas due to their mass-market appeal, the wooden clothespin remains a symbol of traditional home life and sustainable living.

So what’s the greater laundry tragedy: socks vanishing in the wind or disappearing in the dryer? Let us know what you think of this story — and be sure to share it so others can weigh in too!